My Topeak Joe Blow bicycle air pump stopped pumping air. Repair took about 30 minutes. That includes the time I spent eating a sandwich for lunch.

When an air pump stops pumping air, it’s generally because the rubber o-ring attached to the end of the plunger has worn out. If you can get at that o-ring and find the correct replacement part, repair should be pretty easy. Given that quality floor pumps run $40 and up these days, a little time spent in repair might be worth the effort for you. Plus, you can have fun getting your hands a little dirty!

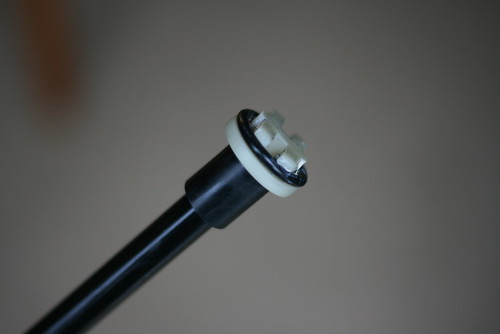

There’s not much to disassembly on my specific model: the Joe Blow Sprint. You just need a 1¼ inch wrench to loosen the handle and a 4 mm hex key to remove the base from the bottom of the barrel.

Once you unscrew the caps and bolts, use a little elbow grease to remove all of the parts. Work over a clean surface to ensure you don’t lose any tiny parts.

For my pump, the o-ring is likely a little worn, but the real problem was beach sand in the bottom of the barrel! I cleaned the grit from the barrel, plunger and from the check valve at the bottom of the pump barrel, and lightly greased the o-ring.

Regular automotive grease — including lithium grease — reduces the life of rubber and plastic parts. To ensure maximum life, you should use a silicone grease inside of air pumps. In real life, though, very few people actually use silicone grease in pumps.

If you need to replace the o-ring, some bike shops have air pump rebuild kits that include o-rings and other small, breakable parts such as springs and valves. You might also bring your old o-ring to the hardware store to find a match. Finally, you can purchase a rebuilt kit online for a little over $6 from Jenson USA.

Cheaper pumps may have the caps glued onto a plastic barrel. These are not easily repairable.

I had a cheap floor pump where the head actually broke. Just the Presta side. I had it laying around the shop for about 2 years (I bought a replacement) and planned on fixing it, just never got around to it. I finally decided a floor pump might be nice to have at work, so I picked up a Topeak replacement hose and head and it fit just right. Plus the hose was nearly a foot longer than the original. Great writeup on the full disassembly. A few bucks is way better than paying full price, and although I did just that, I doubt I would have ever justified having a floor pump at work. I have to say I’m pretty glad it worked out for me!

• Good series of photos! Quite sutiable for Instructables, even.

Oh yeah, good idea. Thanks for the suggestion.

This subversive post tempted me to start taking apart perfectly good pumps!

That’s pretty funny. After typing this up I disassembled 2 more pumps, an old frame pump and the brand new ‘replacement’ floor pump.

Sent from my Googaw

Nice job, if there is video, it’s better. Anyway, thanks for sharing.

Your photos are great, better than anything else I can find. But how did you get the bottom off? You show a picture removing several screws. I have a slightly older model than yours, but everything looks identical so I think you could help me. Thanks!

Exactly what I needed. Great post!

Thanks for this guide as the O ring had failed in my pump. I went to a local hardware store and was able to find an assortment of O rings. In case anyone needs to know the size of the O ring that worked for me, it is #18 which is 1 3/16″ OD x 15/16″ ID. Now my pump is back in action for under $1 in parts.

I bought my 2007/02 Joe Blow Sprint rebuild kit from EBay seller for +/-30AUD, 01/2022. [N/A in AU due to our usual planned obsolescence measures.] It had learned that pneumatic handle trick referred to above, then abruptly failed – after all those years of weekly use! But I like it. Today I finally installed those parts – 1. O ring that seems too baggy cf. original [caked with grease and alu dust from barrel] 2. New adapters, bucket seals for twin head. Not a packet full of fiddly bits at all! Applied MX6 INOX grease [a local silicon substitute] to piston & seal after cleanup. Sadly it doesn’t develop pressure – suspect issue with transfer port and or relief valve. My pump plinth appears pressed on but may as well try removal.

@Naomi bummer the repair didn’t work out for you.

Thank you – your guide helped a lot.

I took everything apart, removed the grease at the large O-ring, cleaned everything, added silicon grease (used for pedal O-rings and front fork suspension service) to the large O-ring and the small O-ring at the bottom spring.

The pump works way better.